A gas furnace is a crucial part of the domestic and industrial sectors. The main purpose of a gas furnace is to maintain the required temperature either for keeping the environment warm or to make fine products. The creation of many products and the precise happenings of various processes requires a controlled atmosphere and a furnace can form it conveniently. If the gas flows directly into your furnace then there is a chance that your furnace might not operate efficiently. It means that the pressure of the gas is one of the most significant factors in the accurate operations of a furnace. It helps to form the required atmosphere by controlling the process variables.

Today the latest gas furnaces contain a number of features including a pressure controller. The main purpose of using this device is to ensure the smooth and safe operation of the furnace.

Here we have listed some points to show the importance of a proportional solenoid valve controller in furnaces:

Maintains a Constant State of Pressure:

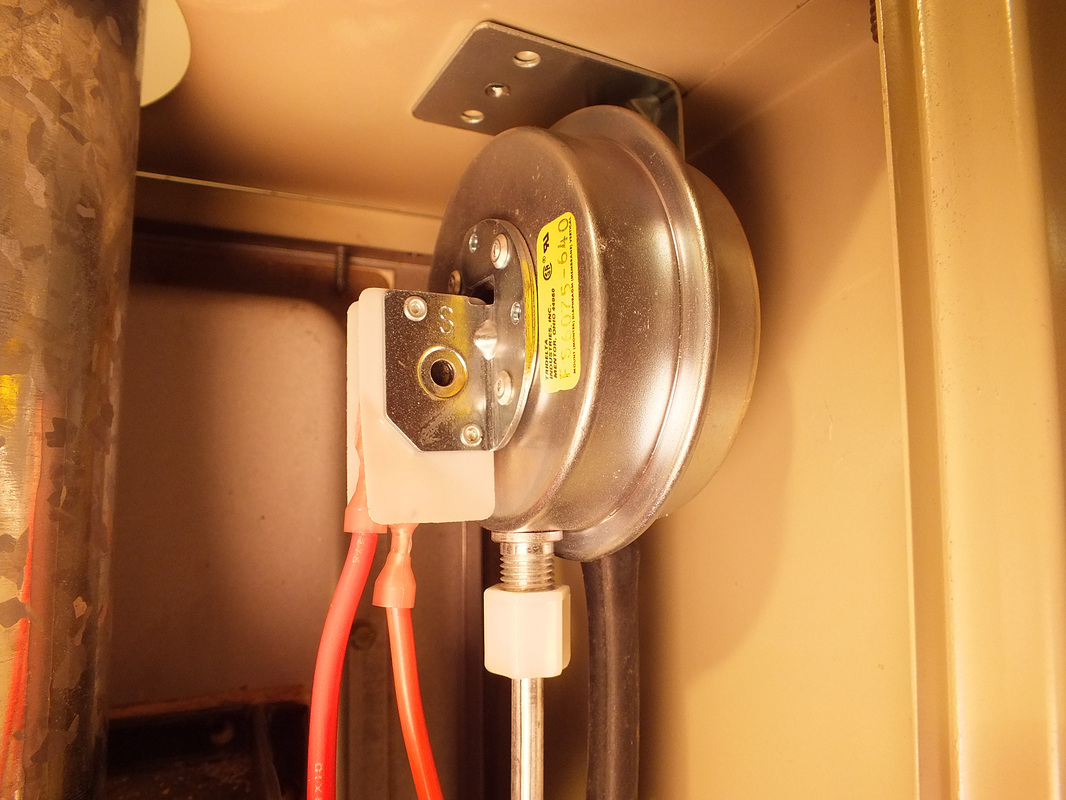

source: pinterest.com

A pressure control manages the pressure of the gas and keeps it equal to the required value by opening and closing the passage of the gas. This ability of proportional flow control to manage the pressure enables the operator to maintain a moderate temperature inside the furnace for the preparation of a product. For instance, bakery items are created inside a furnace because they require a certain temperature to cook precisely.

A too-low pressure and fluctuations have a negative impact on the temperature and the efficiency of the furnace. On the other hand, high pressure is also not suitable for having efficient performance from a furnace. A high pressure of gas can cause the furnace to overheat and this excess heat can damage the internal components and the product.

Provides an Element of Safety:

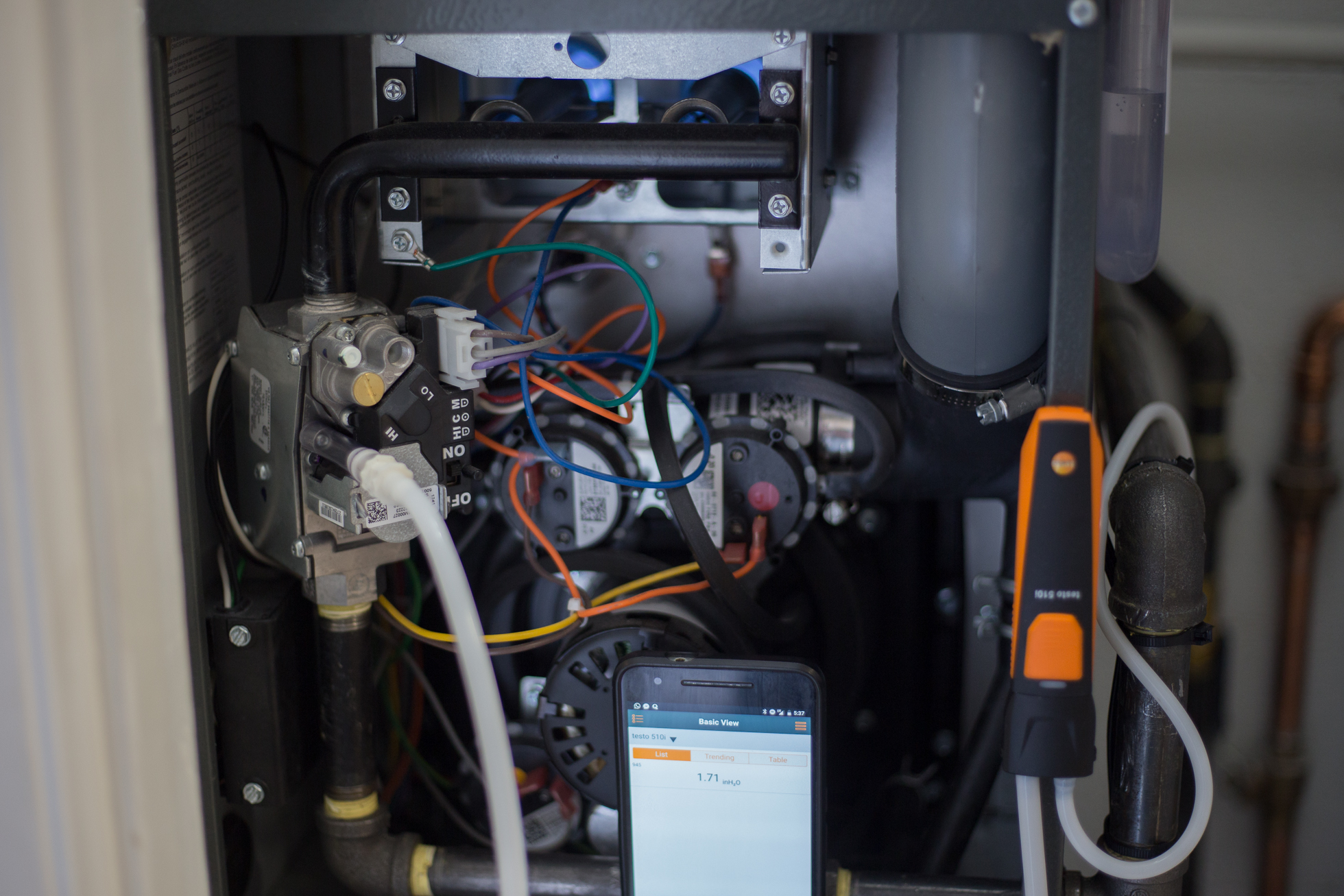

source: pinterest.com

When the pressure of the gas is high then the safety is at risk. Because a high pressure of gas causes overheating inside the furnace. This overheating can result in fire. A furnace fire is very dangerous because it does not have the visible flame or smoke that we usually see in a normal fire. Meanwhile, the detection of furnace fire is not an easy thing. A high pressure controller can control the pressure of the gas for the precise operations of a furnace. It ensures the safety of the system, raw materials and workers. It keeps the pressure and other process variables under control.

Reduce the Consumption of Energy:

source: pinterest.com

Operating a furnace at high pressure means spending high energy. When the pressure is high the system has to exert more force in creating heat and pushing this heat. As a result, the furnace has to work hard and it consumes more energy and fuel in maintaining the required temperature and you will have to pay high energy bills. In this situation, an electronic pressure control can be very helpful. It can easily cut down energy bills and the consumption of the gas.

Final Words:

A pressure controller serves a key role in the accurate and smooth operations of a gas furnace. It allows the furnace to maintain the required atmosphere without consuming excess energy while maintaining a safe working environment.