Introduction

Rubber, a protean material known for its pliantness and continuity, finds wide use in colorful endeavors ranging from automotive to manufacturing. Still, working with rubber frequently requires a perfect slice to produce intricate shapes, factors, and products. Rubber slice, an abecedarian process in the rubber industry, involves colorful ways that feed specific operations. This composition delves into the world of rubber slicing, exploring its ways, operations, and the role it plays in different sectors.

Understanding Rubber Cutting

Rubber slicing is the process of shaping rubber accoutrements into desired forms, sizes, and patterns. Unlike some accoutrements that can be cut with conventional tools, rubber’s pliantness and inflexibility are technical. The primary ideal of a rubber slice is to achieve clean, accurate, and smooth cuts while maintaining the material’s properties.

Ways for Rubber Cutting

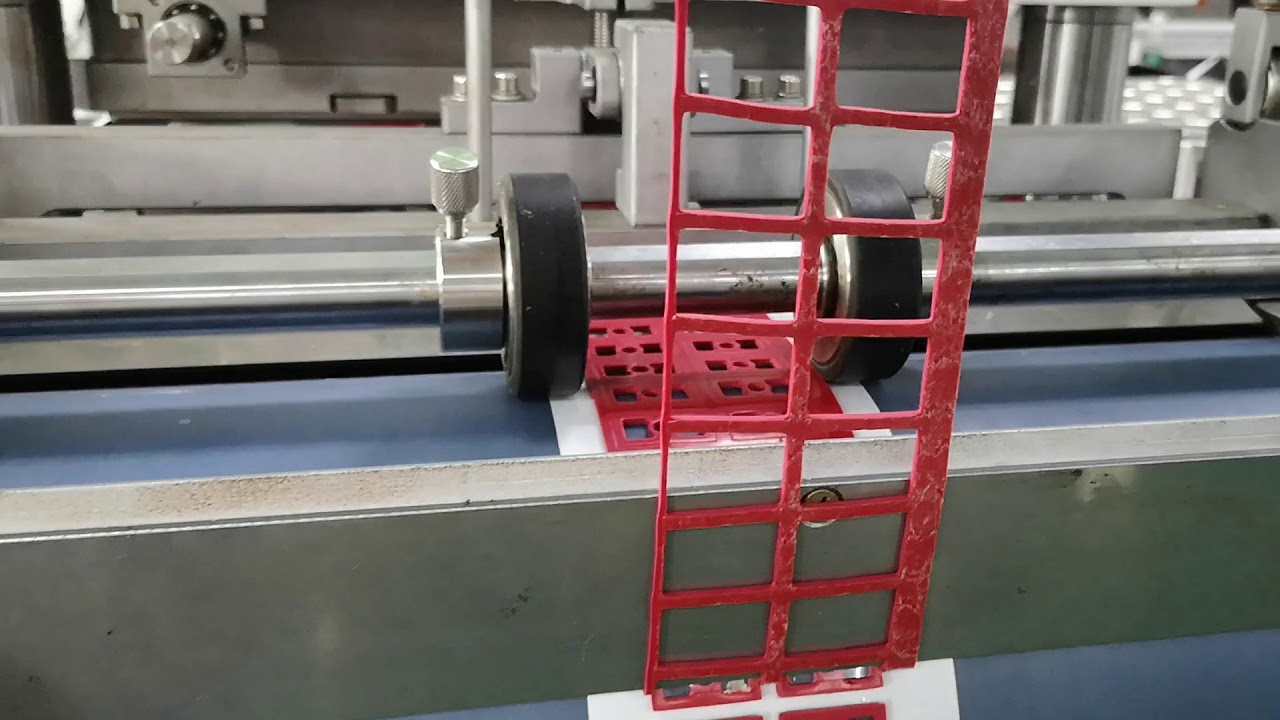

Die Cutting

source: pinterest.com

Die slicing is an extensively used fashion for mass-producing rubber factors with harmonious shapes. A bone, frequently made of essence, is a technical tool with a pattern or shape that corresponds to the requested rubber product. The rubber is placed beneath the bones, and pressure is applied to cut the rubber into the requested shape. Die slicing is effective and suitable for producing gaskets, seals, and custom rubber factors.

Ray Cutting

Ray Slice employs high-powered spotlights to precisely cut rubber accoutrements. It offers excellent perfection and is particularly useful for intricate and detailed designs. The ray’s intensity melts, burns, or vaporizes the rubber, leaving behind a clean and smooth edge. Ray slicing is generally used in industries similar to automotive, electronics, and fashion for creating prototypes, seals, and customized rubber products.

Water Jet Cutting

Water spurt cutting utilizes a high-speed sluice of water mixed with abrasives to cut through rubber accessories. This fashion is known for its versatility and capability to handle the colorful density and consistency of rubber. Water spurt cutting produces minimum heat, reducing the threat of material distortion and maintaining rubber’s properties. It’s frequently used in diligence that bears precise cuts for rubber corridors used in ministry and outfit.

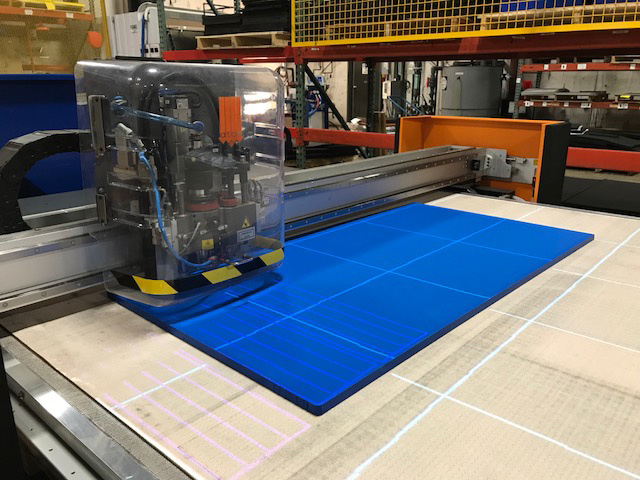

Knife Cutting

source: pinterest.com

Knife cutting involves the use of sharp blades or shanks to cut rubber accoutrements. It’s a protean system suitable for both low and high volumes of product. Knife cutting machines can be programmed to follow specific patterns, making them adaptable to colorful shapes and sizes. This fashion finds operations in casting, footwear manufacturing, and indeed medical diligence for producing rubber- grounded medical bias.

Operations of Rubber Cutting

source: youtube.com

Automotive Industry

The automotive sector considerably uses rubber cutting for manufacturing gaskets, seals, hoses, and vibration dampeners. These factors bear precise shapes and sizes to insure proper functioning and help prevent leaks. Ways like bone slicing and water spurt slicing play a vital part in achieving the delicacy demanded for automotive rubber corridors.

Electronics and Technology

In the electronics industry, rubber slices are pivotal for creating seals and separating factors that cover bias from humidity and dust. Custom rubber keypads, grommets, and seals are frequently manufactured using ray slicing, as it allows for intricate designs and the precise confines necessary for electronic products.

Fashion and Design

Rubber has also made its way into the world of fashion and design. Contrivers use rubber slicers to produce unique textures, patterns, and embellishments for apparel, footwear, and accessories. Ray slice, in particular, enables contrivers to experiment with rubber’s parcels to produce innovative fashion pieces.

Manufacturing and Engineering

source: pinterest.com

Rubber cutting plays a vital role in manufacturing ministries and outfit factors. O-rings, gaskets, belts, and conveyor belts are essential rubber corridors that bear accurate cutways to ensure smooth operations and prevent breakdowns. The trustworthiness of these factors heavily depends on the perfection of rubber slice processes.

Challenges and Considerations

While rubber sliceways offer multitudinous advantages, there are challenges to overcome.

Material Variation

Rubber accoutrements come in colorful phrasings and hardness situations, which can affect how they respond to cutting styles. Adaptations in cutting parameters may be necessary to achieve optimal results with different rubber types.

Precision and Tolerances

source: pinterest.com

Numerous operations demand high perfection and tight forbearance. Achieving harmonious delicacy across a range of rubber accoutrements and densities requires careful estimation of the cutting outfit.

Edge Quality

The quality of the abbreviated edge matters, especially in operations where aesthetics and functionality are essential. Ways like ray slicing tend to give smoother edges compared to cutter slicing.

Conclusion

Rubber slicing is an abecedarian process that contributes to a wide array of diligence. The colorful ways available, from bone slices to ray slices, enable the production of precise and tailored rubber factors. As technology advances, rubber slicing continues to evolve, offering solutions to challenges posed by different rubber phrasings and operations. Whether it’s in the automotive sector, electronics industry, fashion world, or manufacturing realm, rubber slices play a pivotal part in shaping the products and factors we calculate daily.