Like the sharp whistle of a tea kettle announcing a perfect brew, industrial laser cleaning has silently heralded a revolution. Where laborious scrubbing and potent chemicals once reigned, this remarkable technology has brought an era of precision, efficiency, and eco-friendliness, transforming the face of cleaning processes across various industries.

What is Industrial Laser Cleaning

source: pinterest.com

Industrial laser cleaning is a non-contact and non-abrasive process using laser technology to remove contaminants such as rust, oil, oxides, and molds from the surface of materials. This technology harnesses the power of controlled laser pulses to sublimate contaminants, leaving behind a clean and pristine surface that is untouched and undamaged. The popularity of this technology has seen a swift rise due to its promise of high cleaning precision, reduced waste, and adaptability across various materials and industries.

Automotive Industry

In the vast landscape of its applications, the automotive industry has emerged as a predominant user of industrial laser cleaning. This realm frequently battles with stubborn contaminants like rust, grease, and paint, which hinder the production and restoration processes.

The use of laser cleaning in the automotive industry is threefold. It is used in the preparation of metal surfaces for welding, removal of paint for quality control processes, and restoration of classic cars. With its ability to clean without causing damage or deformation, laser cleaning has become the ideal solution for maintaining the structural integrity of automotive parts while ensuring their immaculate cleanliness.

Aerospace Industry

source: pinterest.com

Moving from land to air, the aerospace industry also significantly benefits from industrial laser cleaning. In this high-stakes domain, where every microscopic imperfection could lead to colossal failures, cleanliness standards are astronomically high.

Laser cleaning plays an essential role in mold cleaning for carbon fiber components, ensuring that the final parts are not compromised by any residual contaminants.

Additionally, it is pivotal in surface preparation for Non-Destructive Testing (NDT), where components are checked for flaws. In NDT, the accurate detection of flaws is directly linked to the cleanliness of the surface, making laser cleaning a vital part of the process.

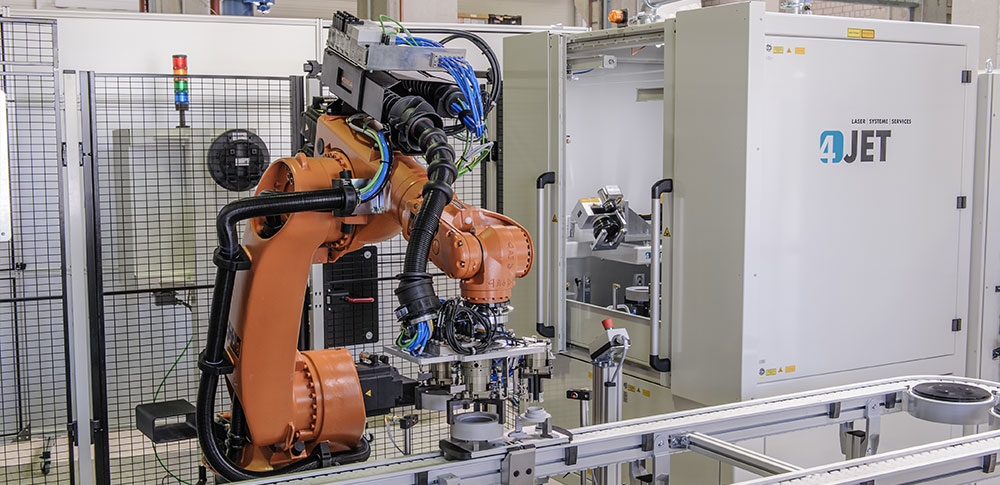

Manufacturing Industry

The manufacturing industry, with its broad range of applications, is another major user of industrial laser cleaners.

Laser cleaning proves its mettle in precision tool cleaning, where traditional methods could damage the tools.

Additionally, it is employed in the preparation of surfaces for painting or coating, ensuring the maximum adhesion and longevity of the finish.

It also finds use in mold cleaning, helping to maintain the quality and consistency of products.

Energy Sector

Laser cleaning technology has found its way into the energy sector as well, particularly in nuclear decontamination and maintenance of solar panels.

Nuclear decontamination involves the removal of radioactive contaminants, a task for which laser cleaning is exceptionally suited due to its non-contact nature.

The regular maintenance of solar panels often requires cleaning to remove dust and grime. Here, laser cleaning is preferred for its non-abrasive character, ensuring that the panels are not damaged.

Cultural Heritage Preservation

source: pinterest.com

Perhaps one of the more unexpected users of industrial laser cleaning is the cultural heritage sector. The technology is used in restoration projects where delicate artifacts need to be cleaned without damaging their structure or historical value.

Maritime and Shipbuilding Industry

Making its wave in the shipbuilding industry, industrial laser cleaning is aiding in the maintenance and refurbishment of vessels. This industry often grapples with issues such as corrosion, marine growth, and layered paint, all of which can drastically affect a ship’s performance and lifespan.

Laser cleaning is used to remove rust and corrosion from ships’ hulls and components, extending the life of the vessel and reducing maintenance costs.

It also plays a pivotal role in surface preparation for repainting or welding, ensuring maximum adhesion and optimal welding conditions.

Rail Industry

The rail industry, with its massive structures and demanding maintenance needs, also finds utility in industrial laser cleaning.

One common application is in the removal of grease and oil from components. Laser cleaning provides a more efficient and environmentally friendly alternative to traditional methods, reducing the risk of contamination and disposal issues.

Moreover, laser cleaning proves advantageous in graffiti removal from train exteriors, offering a non-damaging and efficient solution.

Semiconductor Industry

source: pinterest.com

In the semiconductor industry, where cleanliness and precision are critical, industrial laser cleaning is almost indispensable. Tiny dust particles or residues can disrupt the manufacturing process and lead to faulty products.

The technology is mainly used in the removal of residues from silicon wafers, ensuring they are pristine for the production of semiconductors.

Additionally, it is used in the cleaning of various tools and equipment in the manufacturing process, preventing cross-contamination.

Food and Beverage Industry

Lastly, the food and beverage industry also reaps the benefits of industrial laser cleaning. This sector has stringent cleanliness regulations, and traditional cleaning methods can often introduce contaminants.

Laser cleaning is used in the maintenance of food production equipment, where it excels due to its non-contact nature, which reduces the risk of contamination.

It also shines in the removal of molds from storage containers, contributing to a safer and cleaner food supply chain.

Conclusion

Industrial laser cleaning is a transformative force across a myriad of industries, offering a unique blend of precision, efficiency, and sustainability. Its potential and versatility make it a powerful ally, whether it’s maintaining the gleam on a vintage car, ensuring the safety of aeronautical components, preserving priceless artifacts, or guaranteeing cleanliness in our food supply chain. As we look forward, we can expect to see more industries embracing this technology, guided by its promise to make cleaning processes more efficient and eco-friendly. With industrial laser cleaning, the future of cleanliness is not just bright; it’s laser-focused.